Services: tomography, optical scanning, reverse engineering

Ideas must be shaped or they will remain as such.

Tomography, optical scanning, reverse engineering, and 3D printing bring ideas into being.

ENGINEERING TECHNOLOGY

We can tackle important engineering issues with precision and accuracy and solve problems quickly and permanently. AgioMetrix provides the following services:

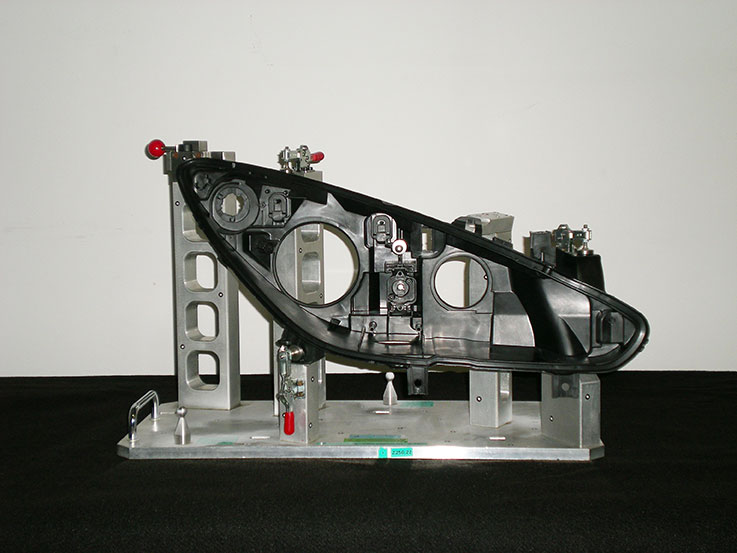

- Optical 3D contactless probing

- Dimensional conformity metrology inspections for quality control

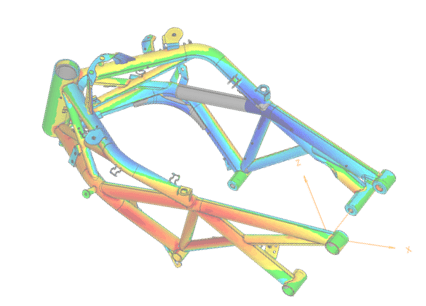

- Support for FEM analysis verifications

- Reverse Engineering

- Product design and industrialisation

- Additive Manufacturing

X-RAY 3D METROLOGY

Rely on a cutting-edge partner for metrology services and hi-tech quality controls.

AgioMetrix provides the following services:

- Metrology with industrial tomography

- Defect inspections with industrial tomography

- 3D contact metrology

- Contactless 3D metrology with laser probe

- Structured light contactless 3D digital metrology

- Reverse engineering

OUR SERVICES

3D DIGITAL SCANNING

3D digital scanning we can obtain:

- 3D colour-scale analysis of objects from a few millimetres to several hundreds of meters,

- Personalised report,

- Analysis tolerance customisation,

- Absolute and relative thickness analysis,

- Specific section measurements,

- Non-destructive testing,

- Digital microscopy.

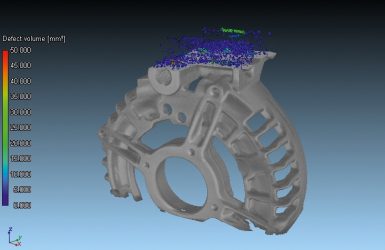

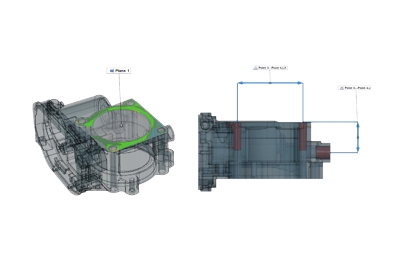

INDUSTRIAL TOMOGRAPHY

X-ray tomography is a non-destructive inspection technique which is rapidly growing in the industrial field. It enables to:

- Promptly detect millions of points of a specific component, both externally and internally,

- Simultaneously analyse different components,

- Overlap the scan and the native CAD model,

- Analyse the whole object deviations,

- Detect hidden defects, porosities, and inclusions without sectioning the piece.

We carry out the following three-dimensional controls:

- Internal/external three-dimensional colour-scale analysis,

- Internal/external 3D full reconstruction of the object,

- Accurate internal sections of the object in measurement,

- Absolute and relative thickness analysis,

- Internal analysis of complex assembled pieces,

- Non-destructive defect inspections.

Fields of application

High power mini-focus CT – 600kV–1500W

Automatic CT Metrology – 3 µm + l/100 (SD)

Metrological Micro-focus CT

Linear accelerator Linac

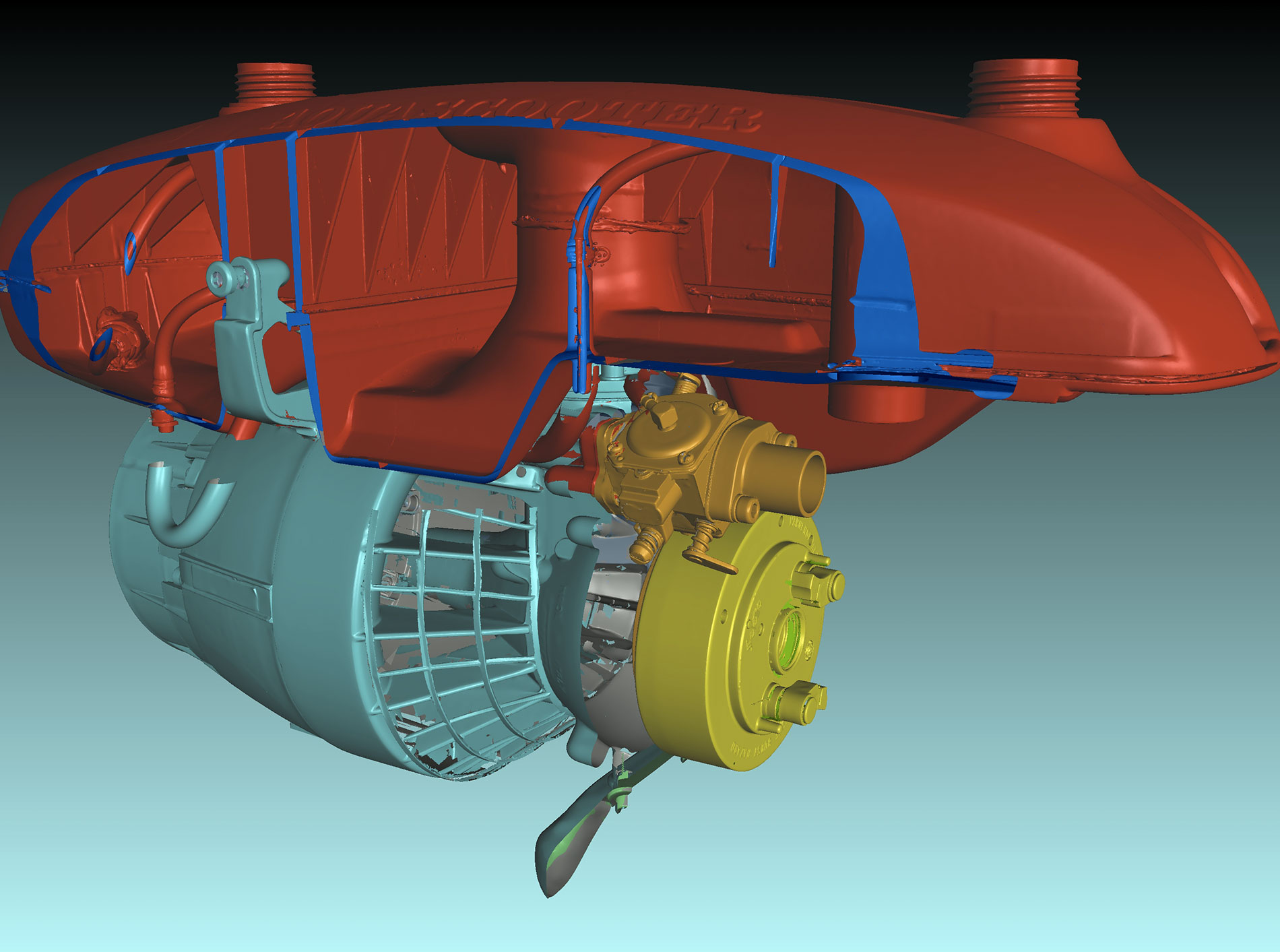

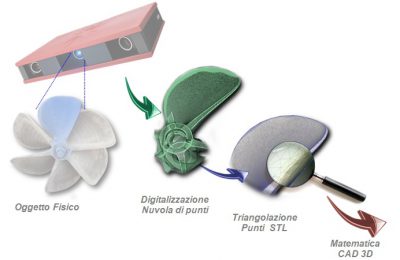

REVERSE ENGINEERING

Reverse engineering is a process aimed at reproducing the three-dimensional structure of an object, device, or machinery. Whatever the shape of the physical model, we are able to obtain CAD data suitable for:

- Identifying alterations, wear, or deformations,

- Reproducing complex shaped objects,

- Reproducing soft and flexible objects,

- Object preservation,

- Tool cutting path optimisation,

- FEM analysis support,

- Prototype manufacturing.

QUALITY CONTROL

Thanks to our wide portfolio of measurement systems and technologies we can perform 3D and 2D geometrical & dimensional conformity checks on samples of every size and shape always with the highest possible accuracy available on the market. In details:

- 2D measurements according to customer’s control drawings,

- GD&T analysis,

- 3D comparison in colour mapping,

- Absolute and relative wall thickness analysis,

- SPC analysis Cp e Cpk,

- Automated controls with robot for process performance monitoring.

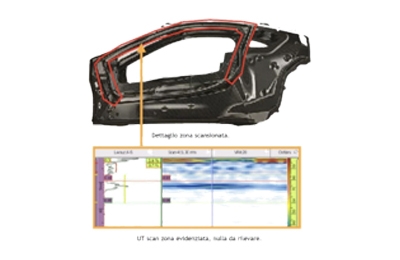

NON-DESTRUCTIVE-TESTING (NDT)

Non-destructive testing on any product. We can perform:

- RX radioscopy both digital and with film,

- magnetoscopy,

- micro-focus 3D RX tomography for high accuracy metrology,

- high power mini-focus 3D RX tomography (600kV – 1500W) for big size massive parts,

- LINAC linear accelerator 3D RX tomography for very high-density materials,

- dye penetrant,

- Eddy current,

- ultrasonic testing both conventional and phased array,

- conventional and Pulsed thermography.

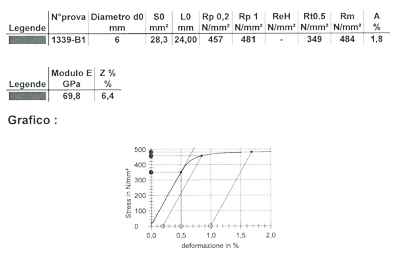

MATERIAL ANALYSIS (MA)

There is a huge market demand for a deep knowledge of every material used starting from the product development phase up to the field rejected parts investigation phase. AgioMetrix group can support customers offering:

- mechanical and technological tests

- macrography,

- micrography,

- chemical analysis,

- corrosion test,

- fracture analysis.

3D DESIGN AND DESIGN STUDY

With AgioMetrix you will find a reliable partner for product design and industrialisation, as well as a high gear to optimise timing.

We provide complete management of work flow:

- Idea, design, rendering,

- Design,

- CAD modeling,

- FEM calculations,

- Rapid prototyping,

- Production launch,

- Quality control,

- Industrialisation.

TRAINING COURSES

We provide full training for Technical, Quality Assurance, and Tomography divisions on the 3D metrology software we use on a daily basis.

We also provide courses and seminars on mechanical design and international regulations of the field.